At Qingdao Eaststar Plastic Machinery Co., Ltd., innovation meets reliability in our advanced Sheet Extruder Die. Designed for the production of high-quality plastic sheets, this critical component ensures uniform thickness and exceptional surface finish across a wide range of materials, from PP and PET to specialized engineering plastics. Whether you're manufacturing packaging materials, automotive interiors, or construction panels, our Sheet Extruder Die delivers consistent performance that boosts productivity and reduces waste. Experience seamless integration with your extrusion line and achieve superior output that meets the strictest industry standards.

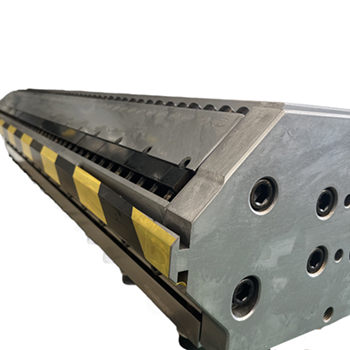

What sets our Sheet Extruder Die apart is its meticulous design and robust construction. Crafted from premium-grade stainless steel and hardened alloys, it resists wear, corrosion, and thermal stress even under continuous operation. The innovative modular lip design allows for quick adjustments and easy maintenance, minimizing downtime. Advanced flow channel engineering ensures homogeneous melt distribution, eliminating issues like die lines or uneven edges. With a focus on precision, each die undergoes rigorous testing to guarantee it performs flawlessly in demanding environments, providing you with a tool that not only meets but exceeds expectations.

Many manufacturers struggle with inconsistent sheet quality, leading to rejected batches and lost revenue. Our Sheet Extruder Die addresses this by offering precise control over thickness and width, ensuring every sheet meets specifications. For instance, in high-speed production lines, variations can cause costly interruptions. Our solution: a dynamically adjustable die lip with real-time feedback systems. Below are key parameters that highlight its capabilities:

| Parameter | Value | Benefit |

|---|---|---|

| Max Working Width | Up to 3000 mm | Ideal for large-format sheets |

| Thickness Tolerance | ±0.1 mm | Ensures uniform product quality |

| Operating Temperature | 200-300°C | Compatible with various polymers |

| Lip Adjustment Range | ±2 mm | Allows fine-tuning on the fly |

This level of precision means fewer rejects, higher throughput, and ultimately, greater profitability for your business.

From large-scale industrial plants to specialized workshops, the Sheet Extruder Die by Qingdao Eaststar serves a diverse clientele. Plastic sheet manufacturers, recyclers, and R&D centers rely on it for producing items like food packaging, signage, and technical components. In automotive sectors, it helps create durable interior panels, while in construction, it facilitates the production of insulating boards and decorative surfaces. If your operation demands consistency, efficiency, and top-tier material output, this die is an indispensable asset.

Imagine running your production line with confidence, knowing that each sheet will be flawless. Users report a significant reduction in material waste and downtime, translating to smoother workflows and higher morale among operators. By eliminating common issues such as edge weaving or thickness variation, this die not only solves technical problems but also fosters a sense of pride in delivering premium products. It’s more than a tool—it’s a partner in achieving your quality goals and driving your business forward.

Unlike standard dies, Qingdao Eaststar's version incorporates a unique thermal management system that maintains even temperature distribution, preventing hot spots that can degrade material quality. Additionally, our dies feature quick-release mechanisms for fast cleaning and changeovers, a rarity in conventional models. Backed by decades of engineering expertise, we offer customized solutions tailored to specific material types and production speeds, ensuring optimal performance where others fall short.

What materials are compatible with this Sheet Extruder Die?

It works efficiently with a wide range of thermoplastics, including PP, PE, PVC, ABS, and PET. For specialized materials like biodegradable plastics, we can customize the die design to suit specific viscosity and thermal properties.

How often does the die require maintenance?

With proper care, routine maintenance is recommended every 6-12 months, depending on usage intensity. The modular design allows for easy disassembly and cleaning, reducing service time and costs.

Can the die be customized for non-standard sheet dimensions?

Yes, Qingdao Eaststar offers bespoke engineering services to adapt the die width, lip configuration, and other parameters to your unique production needs, ensuring perfect fit and performance.

What kind of support do you provide after purchase?

We offer comprehensive technical support, including installation guidance, operator training, and spare parts services. Our team is available to assist with any operational queries to maximize your die's lifespan and efficiency.

Does the die come with a warranty?

Yes, it includes a standard warranty covering manufacturing defects. Extended service plans are also available for added peace of mind.